PIPE BENDS, PIGGABLE BENDS, U-BENDS, RETURN BENDS, HOT INDUCTION BENDS, MILTER BENDS MANUFACTURERS IN INDIA

Pipe bends, piggable bends, u-bends, return bends, Hot Induction Bends, miter bends manufacturers in India

Manufacturer, exporter & suppliers of carbon steel Pipe Bends, stainless steel Pipe Bends, alloy steel Pipe Bends, A403 WP304L, A403 WP316L, ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43

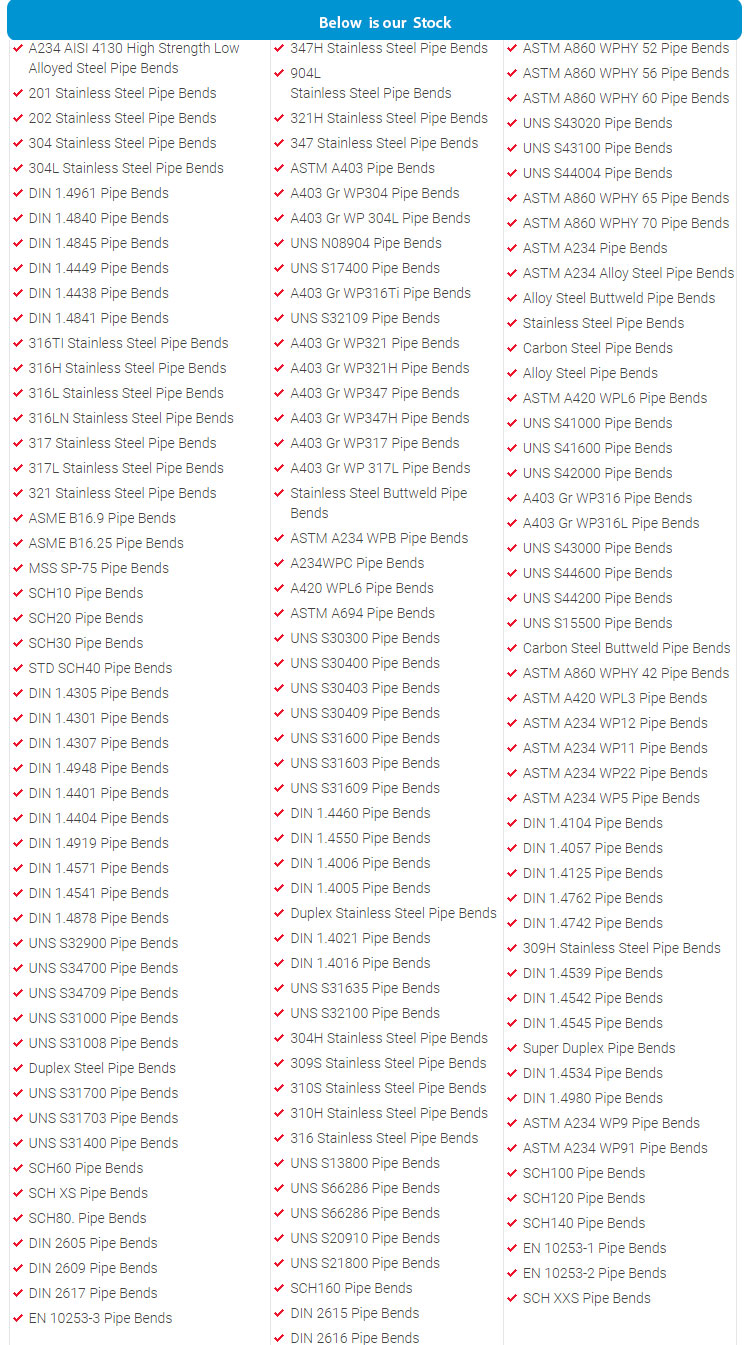

A403 Gr WP304 Pipe Bends, A403 Gr WP 304L Pipe Bends, UNS N08904 Pipe Bends, UNS S17400 Pipe Bends, A403 Gr WP316Ti Pipe Bends, UNS S32109 Pipe Bends, A403 Gr WP321 Pipe Bends, A403 Gr WP321H Pipe Bends suppliers, A403 Gr WP347 Pipe Bends, A403 Gr WP347H Pipe Bends, A403 Gr WP317 Pipe Bends, A403 Gr WP 317L Pipe Bends manufacturers, Stainless Steel Buttweld Pipe Bends, A234 WPB Pipe Bends, A234WPC Pipe Bends, A420 WPL6 Pipe Bends, A234 WP5 Pipe Bends suppliers, A234 WP11 Pipe Bends

We are manufacturer & exporters of Stainless Steel Pipe Bends, Pipe Elbow, Pipe Tee, Pipe Cross, Pipe Reducer, Pipe End Cap, Pipe Bends, Stubend – Lap Joint, Pipe Nipples, Pipe Outlet Fittings for the Oil, Gas, Nuclear, Petro-Chemical and Process Industries. We can manufacture Pipe Bends upto 48″ with wall thickness ranging from 1.5 mm thickness up to 40mm for varied sizes.

Pipe bends/ Hot Induction Bends Production Range

Stainless steel pipe bends, carbon steel pipe bends and special grade pipe bends are widely supplied by us to many industries such as power generation, petrochemical, shipbuilding, paper manufacturing, chemical, pharmaceutical, and fabrication. Ppe cap also known as plugs.

Buttweld Pipe Bends Production Range -Piggable Bends, Hot Induction Bends

Outside Diameter: Seamless Pipe Bends (1/2″ – 24″), ERW / Welded / Fabricated Pipe Bends (2″ – 36″)

Wall Thickness: 3mm – 40mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Bending Radius: R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Product Angle: 0° – 180°

Value Added Services: Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering

Production Grades: Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Copper, Cupro Nickel, Inconel, Monel, Hastelloy

Manufacturing Standards

ASME: ANSI B16.9, ANSI B16.28, MSS-SP-43

DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

EN: EN10253-1, EN10253-2

ASTM A403 – ASME SA403 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

ASME B16.9 – Factory-Made Wrought Fittings Buttwelding

ASME B16.25 – Buttwelding Ends

ASME B16.28 – Wrought Steel Short Radius Elbows and Buttwelding Returns

MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

Stainless Steel Pipe bends/ Hot Induction Bends :

ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Pipe bends/ Hot Induction Bends :

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel Pipe bends/ Hot Induction Bends :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Nickel Alloy Pipe bends/ Hot Induction Bends :

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Duplex & Super Duplex Pipe bends/ Hot Induction Bends :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Type of Pipe Bends

Type A Pipe Bends, Decreased pressure factor

Same wall thickness on the weld ends and on the fi tting body as for a pipe with the same specifi ed wall thickness. Their resistance to internal pressure is less than that of a pipe with the same diameter, same wall thickness and made of the same grade of steel.

The required calculation methods are based on the calculation standards defined in EN 13480-3

Type B Pipe Bends, Full pressure factor

Increased wall thicknesses on the fi tting body, same resistance to internal pressure as for a pipe with the same diameter, same wall thickness and made of the same grade of steel.

The required calculation methods are based on the calculation standards defined in EN 13480-3

Pipe Bends Marking

Each fitting must be permanently marked.

Marking through hard stamping.

- Manufacturer‘s mark or logo

- Country of manufacture (ISO-Code)

- “EN2” as reference to this standard

- “B” for fittings of type B

- Steel name or steel number

- “W” (for welded fittings or fittings that are manufactured from welded pipes)

- Cast number or code number

- Mark of the inspection representative

- Outside diameter D*

- Wall thickness T*

Preparation Pipe Bends for shipment, handling and packaging

EN 10253-2 Fittings & Pipe Bends are delivered with or without surface protection at the discretion of the manufacturer.

EN 10253-4 Fittings & Pipe Bends are delivered by the manufacturer in normal packaging, without surface protection, and without end protectors (caps). Special packaging, protective coverings, and end protectors (caps) can be agreed.

We are having our sub dealers & distributor with adequate stock of SS Pipe Bends in India, United States, UK, Italy, Canada, UAE, Iran, South Korea, Indonesia, Saudi Arabia, Germany, Malaysia, Thailand, Venezuela, Spain, Mexico, Turkey, Poland, France, Australia, Singapore, Brazil, Netherlands, Russia, Vietnam, Colombia, Bangladesh, South Africa, Iran, Iraq, United Arab Emirates (Uae), Qatar, Dubai, Abu Dhabi, Bahrain, Oman, India, Kuwait, Turkey, Yemen, Syria, Jordan, Cyprus, Portugal, Russia, Norway, Germany, France, Egypt, Singapore, Malaysia, Indonesia, Thailand (Bangkok), Vietnam, South Korea, China, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar, Taiwan, Cambodia, Malta, Italy, United Kingdom (Uk), Spain, Ukraine, Netherland, The Republic Of Congo, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Israel, Czechia, Albania, Australia, Perth, Tanzania, Finland, Belgium, Greece, Czech Republic, Ireland, Croatia, Slovenia, Equatorial Guinea, United States Of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Switzerland, Slovakia, Tunisia, Nigeria, Algeria, Angola, South Africa, Libya, Gabon, Philippines & Sudan for quick delivery of Carbon Steel Elbow with mill certificate & all required documents.

Origin: Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin

We offer fastest delivery of A234 WP11 Elbow in Mumbai, Lucknow, Coimbatore, Imphal, Mysore, Ratlam, Delhi, Kanpur, Darjeeling, Jalandhar, Nagpur, Solapur, Kolkata, Allahabad, Dehradun, Jammu, Nashik, Srinagar, Chennai, Ahmedabad, Faridabad, Jamshedpur, Bhadravati, Chattisgarh, Durgapur, Asansol, Hospet, Bellary, Visakhapatnam, Nellore, Surat, Bangalore, Chandigarh, Ghaziabad, Jhansi, Patna, Siliguri, Hyderabad, Amritsar, Noida, Kochi, Pune, Thiruvanthapuram, Jaipur, Aizawl, Guwahati, Kozhikode, Raipur, Vishakhapatnam, Jabalpur, Bhopal, Gwalior, Ludhiana, Rajahmundry, Thane, Agra, Bhubaneshwar, Gurgaon, Madurai, Rajkot, Varanasi, Bhilai, Haridwar, Meerut, Ranchi, Ahmednagar, Akola, Amravati, Aurangabad, Baramati, Beed, Bhandara, Bhiwandi, Buldhana, Chandrapur, Chimur, Dahanu, Dhule, Dindori, Erandol, Gadchiroli, Hatkanangle, Hingoli, Ichalkaranji, Jalgaon, Jalna, Salem, Karad, Khed, Yavatmal, Kolaba, Kolhapur, Kopargaon, Latur, Malegaon, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Rajapur, Ramtek, Ratnagiri, Raver, Sangli, Satara, Shirdi, Shirur, Solapur, Thane, Wardha, Washim, Andhra Pradesh, Jammu and Kashmir, Nagaland, Uttarakhand, Haryana, Lakshadweep, Arunachal Pradesh, Jharkhand, Odisha, West Bengal, Himachal Pradesh, Assam, Karnataka, Punjab, Andaman and Nicobar Islands, Puducherry, Bihar, Kerala, Rajasthan, Chandigarh, Meghalaya, Chhattisgarh, Madhya Pradesh, Sikkim, Dadar and Nagar Haveli, Mizoram, Goa, Maharashtra, Tamil Nadu, Daman and Diu, Tripura, Gujarat, Manipur, Telangana, Delhi and Uttar Pradesh in India.