JACKETED VALVES MANUFACTURERS IN INDIA

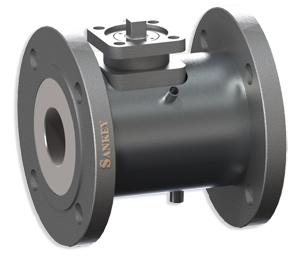

½” To 4” (FB & RB ) Class #150 Two Piece Ball Valve Description : We offer a range of FULL JACKETED BALL VALVES. The jacket covers the body from one flange to the other flange. The body is modified by adding oversize flanges. Example: a 3″ x 4″ jacketed valve has the nominal bore of 3″ (DN 80) and the flange size is 4″(DN 100). This to allow enough space for bolting clearance. |  |

Features & Benefits :

|  |

Materials Body, Ball & Seat: WCB/CF8/CF8M /Others On request |  |

Jacketed Ball Valves

Single Piece Design

Regular (Reduce) Bore Fully Jacketed Ball Valve

Flanged End Connection

Hand Lever / Gear / Pneumatic Operation

Bemcon offers a range of Fully Jacketed Ball Valves. The jacket covers the body from one flange to the other flange. The body is modified by adding oversize flanges. As example: 2″ x 3″ Jacketed Ball Valve has the nominal bore of 2″ (DN 50) and the flange size is 3″(DN 80). It allows enough space for bolting clearance.

Jacketed Ball Valve Dimensions

Jacketed Ball Valve (Full Jacketed Ball Valve)

Full Jacketed Ball Valve

Half Jacketed Ball Valve

Three Way Jacketed Ball Valve

Bemcon offers a range of Fully Jacketed Ball Valves. The jacket covers the body from one flange to the other flange. The body is modified by adding oversize flanges. As example: 2″ x 3″ Jacketed Ball Valve has the nominal bore of 2″ (DN 50) and the flange size is 3″(DN 80). It allows enough space for bolting clearance.

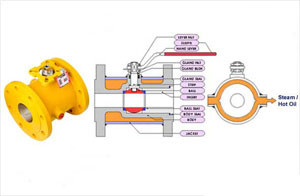

The Jackets assure consistent valve Heating or Cooling of the process media to prevent crystallization or seizing of flow media. The Jacketed Ball Valve (Heating Jacket Ball Valve) with very well design to help the high temperature steam or oil flow over the valve ball & body parts to keep the media liquid. This applies especially to media like bitumen and liquid sulfur. In addition, the efficient flow of media is ensured through the elimination of pockets.

Steam, can be used as carrier for heating media. Following quality assurance rules, every valve is tested again after the Jackets have been welded (Fabricated) to the body. Jacket Hydraulic & Air Test is carried out at 6.0 Kg. /Cm2.

Generally standard Jacketed Ball Valves are delivered in carbon steel and different types of stainless steel materials. Other special materials are available upon special request.

Bemcon Jacketed P.T.F.E. seated Ball Valves gives Zero Leakage, Tight Shut-Off and Low Torque with easy smooth operation at temperature ranging from -20° C. to +220° C. Electro-Polished, Buff Finish & Ultra clean valve also provided for Food & Pharmaceutical Industries on request.

VALVE OPERATION: Bemcon Ball Valves are generally supplied with manual hand lever or gear unit operated, depending on valve size. Citizen Metals also offering Ball Valves with either Pneumatic or Electrical actuator operated for automation.

WIDE RANGE OF BODY SEAT, SEAL & PACKING

Bemcon Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) / PEEK to suit special requirement of client.

|

|

Design & Testing International Standard:

| Valve Design | : BS 5351 / ANSI B 16.34 / API 6D |

| Pressure Testing | : BS 6755 Part II / API 598 / API 6D |

| Face To Face | : As Per ANSI B 16.10 |

| Flange Drilling | : ANSI B 16.5 / BS 10 Table / DIN / IS 6392 |

| Size Range | : ½” x 1″ To 8″ x 10″ |

Material of Construction:

| Body / Insert: Cast Carbon Steel to ASTM A 216 GR. WCB, Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M |

| Ball: Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M, Hast Alloy B / C, ASTM A 351 GR. CN 7M (Alloy 20) |

| Stem: AISI 410 (S.S. 410 13% Cr. Steel), AISI 304 (S.S. 304), AISI 316 (S.S. 316), AISI 304L (S.S. 304L), AISI 316L (S.S. 316L), Hast Alloy B / C, Alloy 20 |

| Ball Seat / Gland Seal / Stem Seal: P.T.F.E. Virgin, P.T.F.E. Glass Filled, P.T.F.E. Carbon Filled, Grafoil |

| Jacket Material: M.S., S.S. 304, S.S. 316, S.S. 304L, S.S. 316L |

Jacketed Ball Valve Range:

Jacketed Ball Valve, Jacketed Ball Valve Manufacturer, Steam Jacketed Ball Valve Exporters, Sulphur Steam Jacketed Ball Valve, Sulfur Jacketed Ball Stockist, Sulphur Ball Valve Manufacturer, Sulfur Ball Valves Exporters, 3 Way Jacketed Ball Valve Exporters, 3 Way Steam Jacketed Ball Valve Manufacturer, Jacketed Ball Valve Flanged End, Hand Lever Operated Jacketed Ball Valves , Gear Operated Jacketed Ball Valve Manufacturer, Pneumatic Operated Steam Jacketed Ball Valves, Pneumatic Actuator Operated Jacketed Ball Valves, Pneumatic Actuated Jacketed Ball Valves, Air Operated Jacketed Ball Valve, Remote Operated Jacketed Ball Valve India, Half Jacketed Ball Valve Manufacturer, Full Jacketed Ball Valves, CS Steam Jacketed Ball Valves (Cast Steel Ball Valve), SS 304/304L Jacketed Ball Valve Manufacturer, SS 316/316L Jacketed Ball Valve Exporters, Jacketed Ball Valve for Sulphur, Steam Jacketed Ball Valves for Naptha, Jakceted Ball Valve for Bitumen, Jacketed Ball Valves for Sulfur Application, Jacketed Ball Valve for Asphalt, Jacketed Ball Valve Pneumatic Operated, Jacketed Ball Valve Manufacturer, Exporter & Stockist.

Valves can be jacketed with a fabricated (weld-on) jacket or a ControHeat® bolt-on jacket. We design, fabricate, and test our valve jackets in accordance with the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1. All valves are pressure and leak tested before and after jacketing. There are numerous jacketing considerations, including flange size, full or partial coverage, types and locations of heating medium connections, bonnet jackets or additional heat coverage for specific areas, and materials of construction. Before specifying fabricated jacketed valves, designers should carefully consider the thermal requirements of the process along with the flange sizes and valve types to be used. For example, most large, full-port ball valves are available only in two- or three-piece configurations. Fabricating full jackets on these types of valves can be very expensive. Metal-seated ball and plug valves are also difficult to jacket without compromising leak-rate standards. In these instances, designers may be better served to consider ControHeat® bolt-on heating jackets. |  |

| Type A: Partial Jacket, Core-Size Flanges. The original valve body is maintained. The jacket terminates a short distance from the back of the flange. Type A jacketed valves are used with swaged and non-reducing insert-flanged jacketed piping where broad process temperature ranges are acceptable. |  |

| Type B: Full Jacket, Jacket-Size Flanges. The valve body is lengthened, and the flanges are replaced with oversize flanges. The jacket covers the body of the valve and extends flange to flange, terminating at the back of the oversize flange. The new face-to-face dimension is the same as a standard valve of size equal to the flange size. For example, a Type B 3-in. X 4-in. jacketed plug valve has the face-to-face dimension of a 4-in. plug valve. Type B jacketed valves are used with standard and reducing insert-flanged jacketed piping. |  |

| Type C: Full Jacket, Core-Size Flanges.. The original valve body is maintained, and the valve flange bolt holes are modified with tapped inserts. The jacket covers the body of the valve and extends flange to flange, terminating on the periphery of the flanges. Type C jacketed valves must be installed by inserting and threading studs from the adjacent mating flanges. The tapped inserts are double-seal welded on front and back to contain the heating fluid. Type C jacketed valves are used with swaged and non-reducing insert-flanged jacketed piping. |  |

| Type D: Full Jacket, Jacket-Size Flanges, Short Body. The valve flanges are replaced with oversize flanges. The jacket covers the body of the valve and extends flange to flange, terminating at the back of the oversize flange. The face-to-face dimension is the same as a standard valve of size equal to the body size. For example, a Type D 3-in. X 4-in. jacketed globe-type control valve has the face-to-face dimension of a 3-in. globe-type control valve. Type D jacketed valves are used with standard and reducing insert-flanged jacketed piping, usually in very dense piping systems where space is limited. |  |